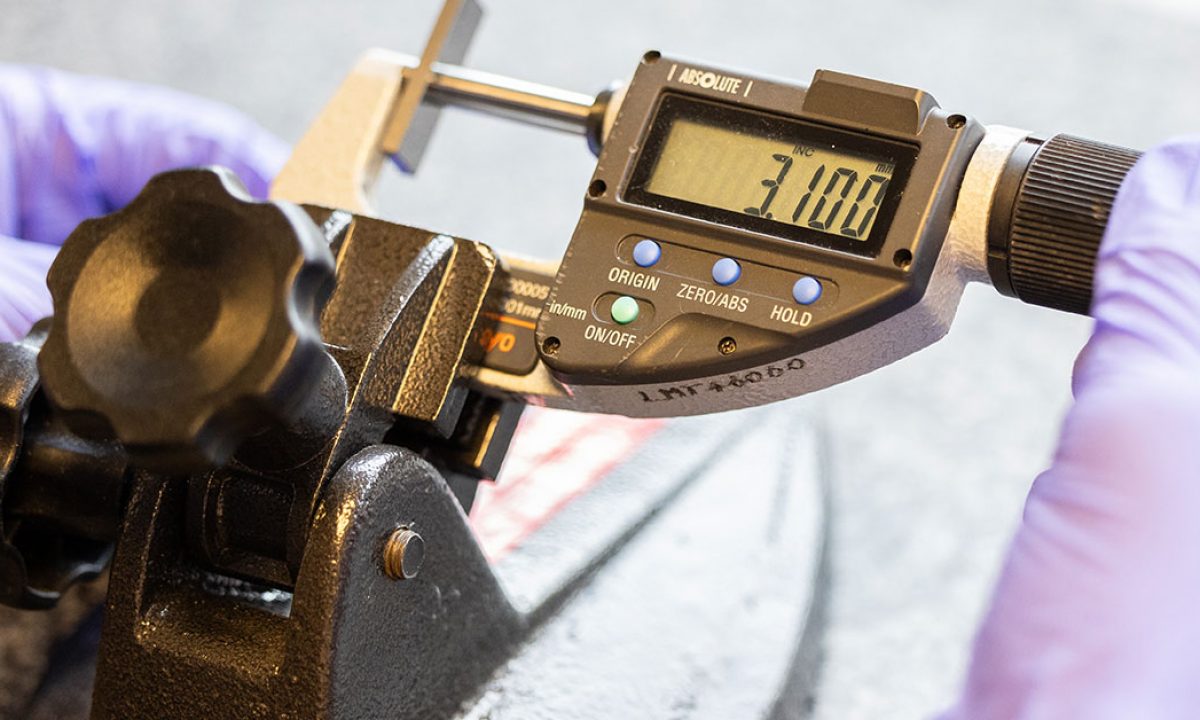

Kalibraatio: Getting Measurements Right, Every Single Time

Kalibraatio is more than a technical routine. For us, it’s the backbone of measurement reliability, product quality, and trust. Whether we are working in manufacturing, healthcare, laboratories, construction, energy, or any industry that depends on accurate data, calibration quietly shapes every result we rely on. When measurements are right, decisions are right. When they’re off, even by a little, the consequences can ripple far beyond what we expect.

In this article, we’ll walk through kalibraatio in a simple, practical, and human way. No heavy jargon. No robotic explanations. Just real-world understanding of why calibration matters, how it works, and why it should be part of how we think, not just something we “do when required.”

What Kalibraatio Really Means

At its core, kalibraatio means comparing a measurement device against a known reference and adjusting it if needed. That’s the technical definition, but let’s bring it down to earth.

Every measuring tool we use drifts over time. Temperature changes, mechanical wear, electrical aging, vibration, dust, and even regular usage slowly push instruments away from accuracy. Kalibraatio is how we bring them back in line.

When we calibrate, we’re asking a simple question:

“Is this instrument telling us the truth?”

And if the answer is “almost” or “not quite,” we correct it.

Why We Can’t Ignore Calibration

It’s tempting to see kalibraatio as a checkbox task. Something for audits. Something the quality team handles. But in reality, calibration affects everything.

When we ignore calibration or delay it, we invite uncertainty into our work. Measurements become guesses. Decisions become assumptions. Over time, this can lead to rejected products, safety risks, customer complaints, or regulatory trouble.

Accurate measurement builds confidence. Confidence builds trust. And trust is what keeps businesses, systems, and relationships running smoothly.

Kalibraatio and Measurement Reliability

Reliability means consistency over time. When we measure the same thing today and tomorrow, we expect the same result. Kalibraatio supports that consistency.

Without calibration:

- Measurements slowly drift

- Small errors become large ones

- Trends become misleading

- Data loses credibility

With regular calibration:

- Measurements stay aligned

- Results are repeatable

- Data remains trustworthy

- Long-term analysis makes sense

This is why calibration isn’t a one-time event. It’s an ongoing process that protects measurement integrity.

The Role of Kalibraatio in Product Quality

Quality starts with measurement. If we can’t measure correctly, we can’t control quality.

Think about it from our perspective. If a product specification says a part must be exactly a certain size, weight, pressure, or temperature, we rely on instruments to verify that. If those instruments are off, even slightly, we might approve faulty products or reject good ones.

Kalibraatio ensures that:

- Dimensions are correct

- Materials meet standards

- Performance matches design

- Customers receive what we promise

In short, calibration is quality assurance before quality assurance even begins.

Compliance and Standards

Many industries operate under strict regulations. Whether it’s manufacturing, pharmaceuticals, food processing, aviation, or energy, calibration is often mandatory.

But compliance isn’t just about avoiding penalties. It’s about accountability.

When we maintain proper calibration records:

- We prove traceability

- We show process control

- We demonstrate responsibility

- We reduce risk during audits

Kalibraatio gives us evidence that our measurements are not just assumed to be correct, but verified.

How Kalibraatio Works in Practice

Calibration isn’t complicated when we break it down.

First, we use a reference standard. This is a tool or value that is known to be accurate. Then we compare our working instrument against it. We record the difference. If the difference exceeds acceptable limits, adjustments are made.

The steps usually include:

- Inspection of the instrument

- Comparison with a reference

- Adjustment if needed

- Documentation of results

The key isn’t just the adjustment. It’s the documentation. Calibration without records is like a promise without proof.

Frequency Matters

One of the most common questions is how often we should calibrate. There’s no single answer that fits everyone.

Calibration frequency depends on:

- How often the instrument is used

- How critical the measurement is

- Environmental conditions

- Historical drift data

Instruments used daily in harsh environments may need frequent calibration. Others, used less often or in controlled settings, may need it less frequently.

The goal isn’t over-calibration or under-calibration. The goal is confidence.

Internal vs External Calibration

We often choose between internal calibration and external calibration services.

Internal calibration works well when:

- We have trained personnel

- We own reference standards

- We need fast turnaround

- Measurements are routine

External calibration is useful when:

- High accuracy is required

- Certification is needed

- Specialized equipment is involved

- Independence is important

Both approaches have value. What matters is consistency and reliability, not where the calibration happens.

Kalibraatio in Digital Systems

As systems become more digital, calibration doesn’t disappear. It evolves.

Sensors, software-driven instruments, and automated systems still rely on accurate inputs. Digital drift happens too. Algorithms depend on clean data. Calibration ensures digital outputs remain meaningful.

In modern environments, kalibraatio often includes:

- Sensor verification

- Software parameter checks

- Data validation

- System-wide consistency testing

Even in automated worlds, calibration keeps humans in control.

Cost vs Value

Some see calibration as an expense. We see it as insurance.

The cost of regular kalibraatio is small compared to:

- Product recalls

- Process failures

- Legal issues

- Lost customer trust

Calibration prevents problems before they become expensive lessons. It’s a proactive investment, not a reactive fix.

Common Misunderstandings

Let’s clear up a few myths.

Calibration does not mean repair.

It doesn’t always involve adjustment. Sometimes the instrument is already within limits.

Calibration is not optional.

Even when not legally required, it’s operationally necessary.

Calibration is not only for labs.

Field instruments, on-site tools, and portable devices need it too.

Once we see calibration as a mindset, not a task, these misunderstandings fade.

Building a Calibration Culture

The strongest organizations don’t treat kalibraatio as a background activity. They build it into their culture.

This means:

- Training teams to respect measurements

- Scheduling calibration proactively

- Reviewing calibration data

- Learning from trends and drift

When everyone understands why calibration matters, it stops feeling like an interruption and starts feeling like protection.

Documentation and Traceability

Calibration records tell a story. They show where we’ve been and how stable our measurements are.

Good documentation includes:

- Date of calibration

- Instrument identification

- Reference standards used

- Results and adjustments

- Next due date

These records support audits, investigations, and long-term improvement.

Kalibraatio and Decision-Making

Every decision we make is influenced by data. Data comes from measurements. Measurements depend on calibration.

When calibration is solid:

- Decisions are confident

- Risks are visible

- Trends are meaningful

- Planning improves

When calibration is weak:

- Data becomes noise

- Decisions become guesses

- Errors hide in plain sight

Kalibraatio strengthens decision-making at every level.

Looking Ahead

As technology evolves, calibration remains essential. New tools, smarter sensors, and advanced systems still rely on accurate references. The future doesn’t eliminate calibration. It demands better calibration.

Automation, remote monitoring, and digital records will change how we manage calibration, but not why we need it.

Accuracy will always matter.

Final Thoughts

Kalibraatio is not just a technical requirement. It’s a promise. A promise that our measurements are trustworthy, our processes are controlled, and our outcomes are reliable.

When we take calibration seriously, we protect quality, ensure compliance, and build confidence in everything we do. It doesn’t shout for attention, but it quietly supports every success.

In the end, calibration is about respect. Respect for data. Respect for standards. And respect for the work we put into getting things right, every single time.